At the core of industrial heat: Frascold launches the Nexus series

Screw compressors for high-temperature heat pumps

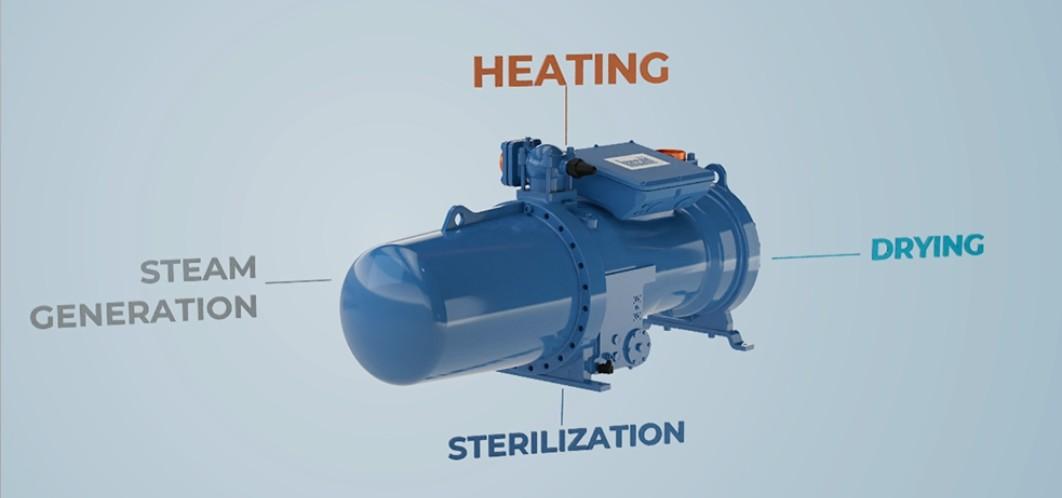

Frascold launches the new Nexus screw compressors for high temperature heat pumps.

In the industrial process heating sector, for years boilers have been the only solution to guarantee high temperatures and operational continuity. Today, however, the evolution of the energy and regulatory framework is calling into question the sustainability of gas-only systems. On the one hand, the increasing volatility of fuel costs makes the management of these technologies more onerous. On the other hand, the acceleration towards climate neutrality, enshrined in the Green Deal, Fit for 55 and REPowerEU, is encouraging the industry to rethink heat generation with a more long-term perspective.

From drying to food processing, to chemical and pharmaceutical processes, the availability of stable and reliable heat remains a fundamental requirement. For these heat-intensive applications, adopting industrial air-water and water-water heat pumps represents a viable alternative to meet a wide range of temperatures, with more efficient and flexible energy architectures. In this sense, the real challenge is to guarantee performance stability and reliability: a requirement fully met by Frascold semi-hermetic high temperature compressors, which enable industrial heat pumps to successfully replace traditional boilers, even in the most demanding applications.

Specifically, Frascold's NEXUS series brings together compressors designed to withstand high compression ratios and operate continuously even under harsh conditions. A technology that combines high operating temperatures, compatibility with low GWP refrigerants and wide application versatility, paving the way for more advanced and sustainable solutions.

Beyond thermal limits: the architecture of Nexus compressors

The new generation of Frascold NEXUS screw compressors is the result of extensive reengineering aimed at enhancing their reliability, even under challenging operating conditions, their performance and application flexibility, in order to meet the different needs of the market. Among the most important interventions is the integration of high-efficiency motors, sized to operate in extreme thermal conditions. In addition, the expansion of temperature limits allows hotter fluids, up to 100° C, to be handled in suction, thus guaranteeing operational stability even in the event of high power consumption. At the same time, the electric plate has been redesigned, featuring an optimized design and developed to withstand the highest temperatures involved. A further modification involved both the bearings, manufactured with new generation materials and the tolerances, designed to compensate for thermal expansions both in suction, up to 100°C, and in delivery, up to 150°C. Frascold also made changes to the lubrication circuit, introducing a specific oil, which reduces the solubility of the refrigerant in the oil, thus ensuring optimal viscosity under all operating conditions. In addition, the crankcase heaters have been upgraded by using up to four electrical heating elements to ensure the optimum temperature and viscosity of the oil before starting the compressors. Finally, the special external coating can withstand temperatures up to 200°C, ensuring long-term surface protection and durability.

Natural refrigerants and high-intensity processes: Nexus performance

From a refrigerant point of view, the range is designed to work with two types of refrigerants: HFO, in particular, R1233zd or hydrocarbons such as butane and isopentane in water-water configuration, guaranteeing maximum versatility in the design of the systems, with a maximum operating temperature of 140°C and a heating capacity of over 1MW.

In terms of performance, the series supports external inverters in the 30–60 Hz range for precise modulation of cooling and thermal capacity, ensuring greater operating stability. The compressors include motors suitable for higher temperatures and a lubrication circuit designed to ensure adequate lubrication even at high speeds, thus reducing mechanical stress and optimising long-term reliability. In terms of operational capacity, NEXUS is ideal for large-capacity heat pumps, with volumetric displacements from 316 to 912 m³/h at 50 Hz and motors up to 300 HP.

Maurizio Mastrapasqua, Product Manager of Frascold states "The reliability of NEXUS compressors has been confirmed by a number of field applications, in particular, an in-depth test campaign conducted at the Danish Technological Institute between February 2024 and July 2025. During these tests, performance and reliability were verified even under the most demanding operating conditions" and he concludes "Frascold is ready to introduce important innovations in the field of high temperatures, with future developments that will take performance to even higher levels.”