HFOs at medium temperature

And the future of refrigeration

A revolutionary system by Geoclima and Frascold with a Honeywell refrigerant helps reduce the carbon footprint.

A renowned Italian corporation and leader in the confectionery market was looking for a flexible and efficient refrigeration system for its new large warehouse, able to guarantee the perfect preservation of its products and at the same time reduce its carbon footprint. The system, developed by Geoclima and Frascold, which uses a Honeywell HFO refrigerant, proved to be the ideal solution.

Among the currently emerging trends set to shape the new face of refrigeration, the growing preference for HFO medium-temperature refrigerants stands out, increasingly used in production and chilling processes as a substitute for traditional fluids. The advantages are many: these refrigerants in fact make it possible to develop energy efficient systems with reduced TCO (Total Cost of Ownership), and by virtue of their extremely low GWP, they already satisfy the restrictions set to be imposed by the F-gas Regulation as of 2022. A perfect example of this trend is the recent collaboration in which Frascold played a key role together with GeoClima and Honeywell, with the aim of developing a refrigeration system for a large warehouse, commissioned by a major Italian corporation and leader in the confectionery market.

THE FOUNDATIONS FOR A SUCCESSFUL COLLABORATION

The partnership between Frascold and Geoclima is well-consolidated and based on the two companies’ shared expertise in the respective production of chillers for air conditioning and refrigeration systems using Frascold semi-hermetic screw compressors. Specifically, the Client commissioned the development of a cooling system for its new warehouse occupying a total space of 30,000 m2, which required considerable load modulation and excellent partial load outputs so as to guarantee the perfect preservation of its products; it was these specifications that determined the design requisites.

ONE PROJECT, TWO CHALLENGES

To develop a technologically advanced solution, which was also high-performance and eco-sustainable: these were the main challenges for Geoclima and Frascold. The new warehouse is characterised by a high turnover rate and therefore variable thermal loads due to frequent loading and unloading operations, with a constantly varying demand for cooling. To this end, a system was required able to provide a consistently adequate level of power, employing sustainable solutions in line with European directives to ensure utmost energy efficiency. The new system reflects the Client’s sensitivity towards the environment and rational use of resources. The End User is in fact committed, in all of its initiatives, to reducing its carbon footprint to a minimum, starting from its raw materials through to its production systems, logistics and entire production chain.

THE SOLUTION: AN EXCLUSIVE MT SYSTEM WITH HFOs

The efficiency and reliability of Frascold compressors enhances the Geoclima solution, consisting in a sophisticated glycol system in which the chillers are proposed in a “medium temperature” version. The units produce glycol at -6 °C using Solstice® ze (R-1234ze) by Honeywell, a low environmental impact HFO with GWP less than 1. To this end, Hydrofluoroolefins (HFO) represent an excellent combination of benefits in terms of performance, safety, cost effectiveness and sustainability. Specifically, by virtue of its characteristics, the Solstice® ze refrigerant is a valid long-term substitute for applications in high-powered chillers and equipment that traditionally uses R134a.

A HIGH-PERFORMANCE SYSTEM

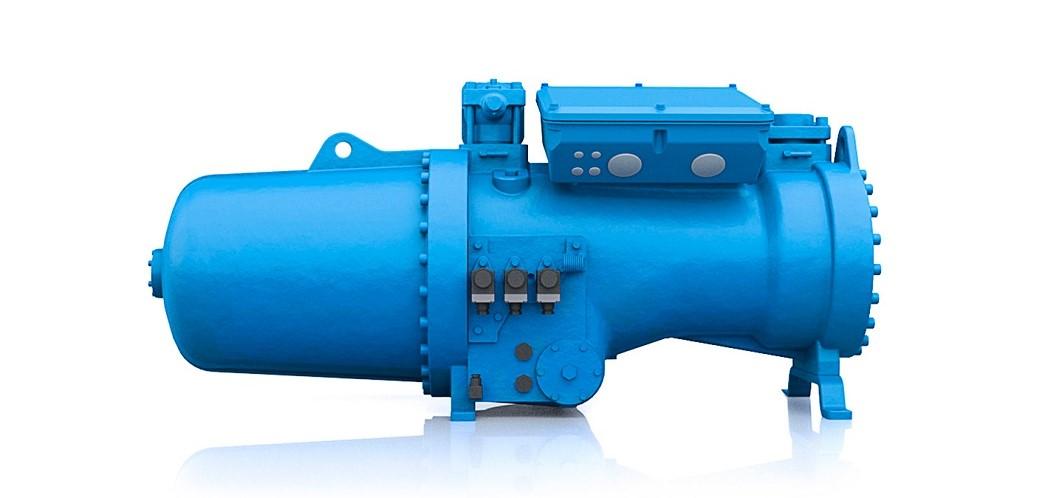

Geoclima proposes a system composed of 3 x 480kW air condensing chillers, each equipped with 4 Frascold semi-hermetic screw compressors having a volumetric displacement of 538m3/h, designed and specifically adapted to suit medium temperature systems, aluminium micro-channel condensers and 12 independent refrigeration circuits. Thanks to the special concept implemented, the refrigeration circuits are intelligently managed by a Proportional-Integral-Derivative controller. This system allows the activation only of the necessary refrigeration circuits and compressors, and the supply - at all times - of thermal power suited to the specific needs of the warehouse, thus ensuring energy consumption commensurate with the system’s effective contingent needs, and therefore allowing a reducedpayback period.

“Geoclima and Frascold created a winning synergy,” declared Paolo Ferraris, CEO of Geoclima Group “as part of which we redesigned the system and compressor in order to achieve the best possible configuration, best exploiting the low pressures and density of the Honeywell Solstice® ze refrigerant with a view towards maximising efficiency. The design choices adopted guarantee a dynamic and customised system for the Client perfectly in line with their specifications. Moreover, the proposed system ensures high-performance and absolute reliability and quality in terms of both the preservation of their goods and optimised energy consumption all year round.” He concluded, “We are extremely satisfied with our collaboration with Frascold: a partnership that has once more proven to be a success, also thanks to the high quality of their components, consultancy, utmost availability and efficiency in offering an excellent service and products designed ad hoc, in just 3 weeks.”

Livio Calabrese, member of the Board of Directors and Sales Director of Frascold, declared: “The collaboration between Frascold and Geoclima for the study and development of HFO solutions began in 2012, when our Companies developed one of the first chillers in the world to use this type of refrigerant. For Frascold, this project represents yet another opportunity to demonstrate the excellence of its solutions and the company’s commitment to consistently guaranteeing fast and efficient solutions, one step ahead of the market. Thanks to our R&D team, we were able to develop a solution with proven efficiency, load modularity and reliability, opting for compressors both with continuous capacity control and with inverters, developed for use with the HFO1234ze refrigerant.”

"Honeywell has long been at the forefront of fluorocarbon technology and we are delighted that Solstice® ze supports the client’s commitment to minimising their environmental impact," declared Julien Soulet, Vice President and General Manager, Honeywell Fluorine Products Europe, Middle East and Africa. “Working in close contact with OEMs such as Geoclima and Frascold to promote the adoption of HFO refrigerants with low GWP is a fast and proven path to enabling Clients to reduce their carbon footprint, while at the same time ensuring utmost performance.”