System with R290 and Frascold screw compressors

206 kW Cold Room at -20°C

Discover the latest outstanding project carried out at a leading pet food manufacturer by Cagnasso Frigoriferi S.r.l. using Frascold compressors.

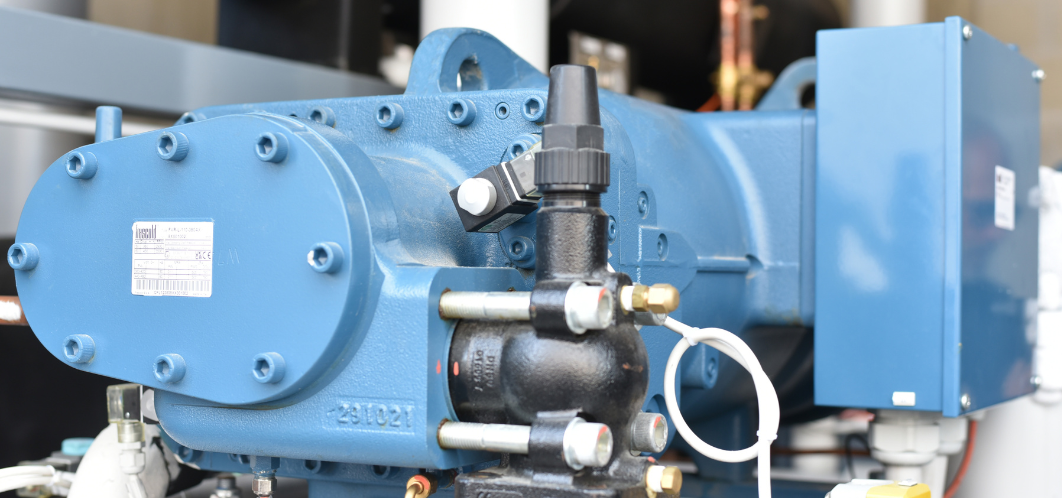

Cagnasso Frigoriferi confirms once again its trust in Frascold compressors for the new propane refrigeration system installed at a major pet food company, specialized in the production of high-quality food for our four-legged friends. The selected solution is the FVR-LT-ATEX semi-hermetic screw compressor for low temperatures with R290 and ATEX Zone 2 certification.

A system carefully designed by Cagnasso Frigoriferi

The client company requested the construction of a sustainable refrigeration plant capable of maintaining a temperature of -20°C in the cold room and preserving its high-quality pet food at its best. Following a thorough evaluation of various refrigerants, R290 gas was selected as the ideal refrigerant for the system and glycol as the carrier fluid to transfer the cooling effect into the room, ensuring greater safety and reliability.

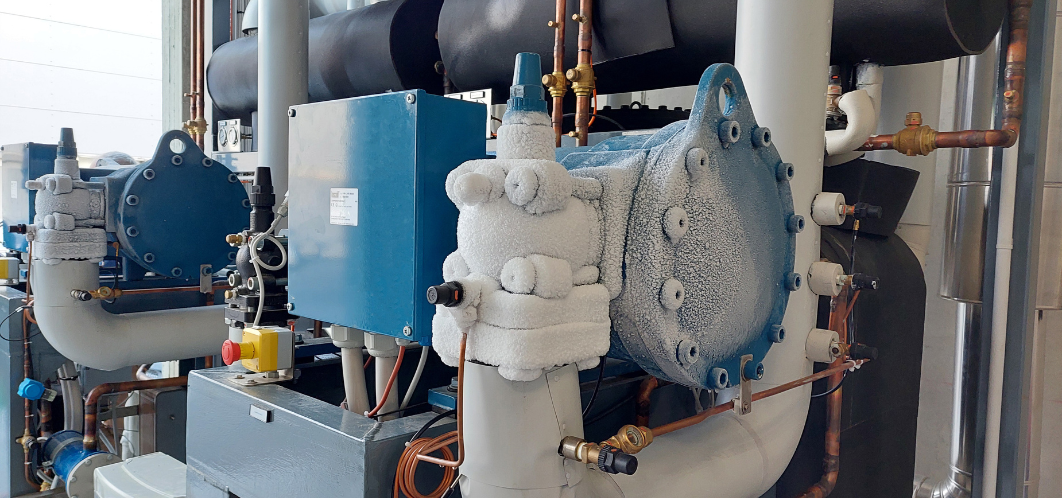

The chiller was built with two FVR-LT-ATEX screw compressors optimized for hydrocarbons, each operating in separate gas circuits with a refrigerant charge of 51 kg each. The total cooling capacity generated is 206 kW.

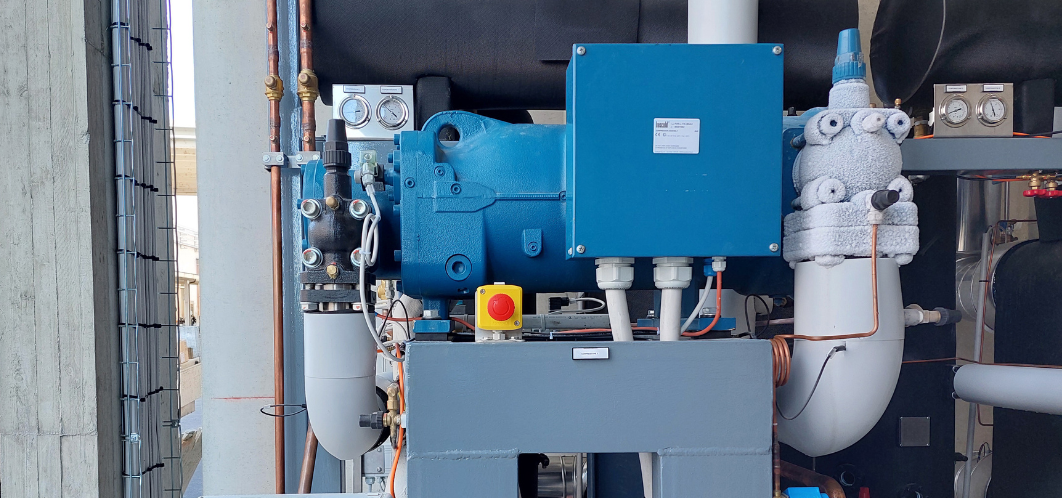

The innovative aspect of the new plant lies in its installation within a dedicated machine room, equipped with forced extraction ventilation and redundant sensors, accessible only to authorized personnel. The entire system is divided into two distinct zones.

The first, an ATEX area, contains the two Frascold FVR-LT-ATEX screw compressors, the oil separators and the evaporators.

The second, defined as the safe control zone, is dedicated to glycol pumping, electrical panels and inverters. Additionally, the microchannel condenser was relocated to the roof of the machine room, also taking advantage of the static head for oil cooling via thermosiphon. Among the key components, Frascold compressors play a crucial role, with the FVR-LT-ATEX screw series chosen for low evaporation temperatures, known for its quiet operation and compact size.

“We have had a long-standing collaboration with Frascold, and their solutions are always a guarantee of innovation and high quality for us. In the case of the system developed for our client, the FVR-LT-ATEX screw technology allowed us to reach low temperatures at high cooling capacities while ensuring a high energy efficiency ratio,” says Maurilio Cagnasso, who concludes, “The combination of the high sustainability of propane and Frascold's technology enabled us to meet all the client’s needs in an innovative way.”