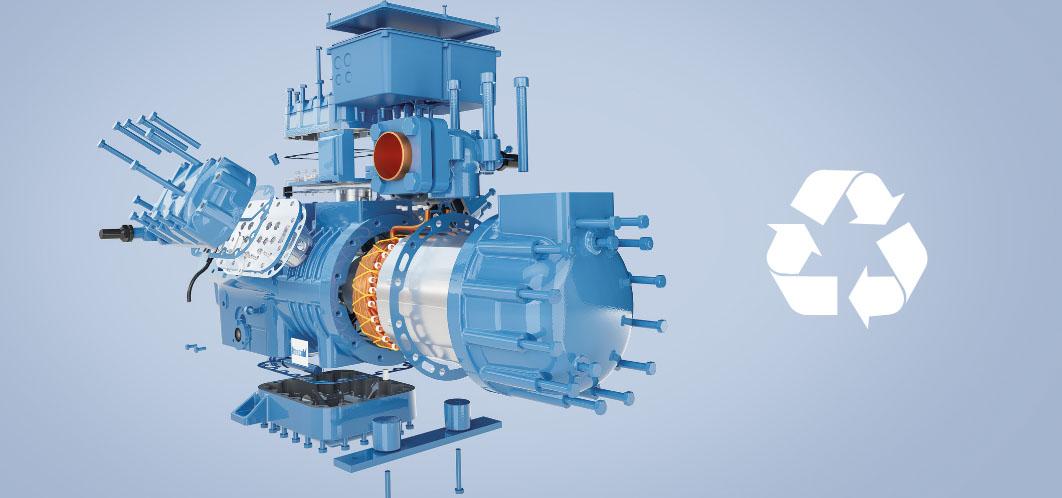

The End-of-Life (EOL) of compressors

A circular approach for true sustainability

Frascold reaffirms its commitment to increasingly tangible sustainability, even during the delicate End-of-Life (EOL) phase of compressors.

This responsible approach aims to reduce environmental impact by promoting virtuous practices and maximizing the value of existing resources.

The company’s philosophy encourages customers and partners to consider every possible maintenance or repair intervention before replacing a compressor. This choice not only extends the useful life of components but also helps limit waste and reduce operating costs. To support this sustainable model, Frascold provides a widespread network of Authorized Service Centers, equipped with specialized personnel who undergo continuous training.

Another tool supporting this vision is the Spare Parts Software, a dedicated platform for managing spare parts. The software allows quick and intuitive access to the components needed for compressor maintenance, improving operational management and reducing downtime. This contributes concretely to lowering environmental impact, thanks to reduced reliance on new equipment and longer machine life cycles.

When repair is no longer possible, a structured process ensures the proper disposal and recovery of materials. Frascold promotes compliance with environmental regulations and industry best practices, guaranteeing that each component is treated according to the highest standards of environmental responsibility.

- Cast iron: sandblasted to remove paint before being remelted in foundries.

- Steel: sent directly for remelting, with no need for preliminary treatments.

- Electric motor: conductive metals such as copper and aluminum can be separated manually or recovered as mixed metal, then processed in specialized plants.

- Brass and stainless steel: recyclable materials remelted for the production of new components.

- Gaskets: classified as mixed waste, disposed of in compliance with regulations at authorized facilities.

Proper End-of-Life management not only helps minimize environmental impact but also enhances resource recovery, fostering a more circular and efficient economy.

To learn more or receive support in managing the End-of-Life of compressors, do not hesitate to contact the Frascold team. Together, we can build a more sustainable future.