Chiller for the food and pharmaceutical sectors

Frascold and A.S.K.I., tailor-made refrigeration

The first chiller preserves fruit in Mali, the second is intended for the pharmaceutical industrial process system: these are the solutions born from the cooperation between Frascold and A.S.K.I. Refrigerazione.

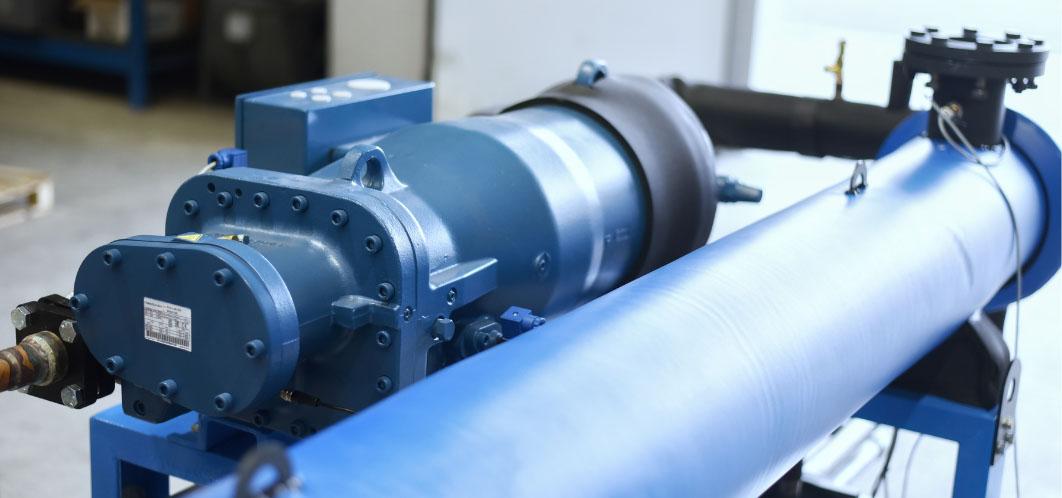

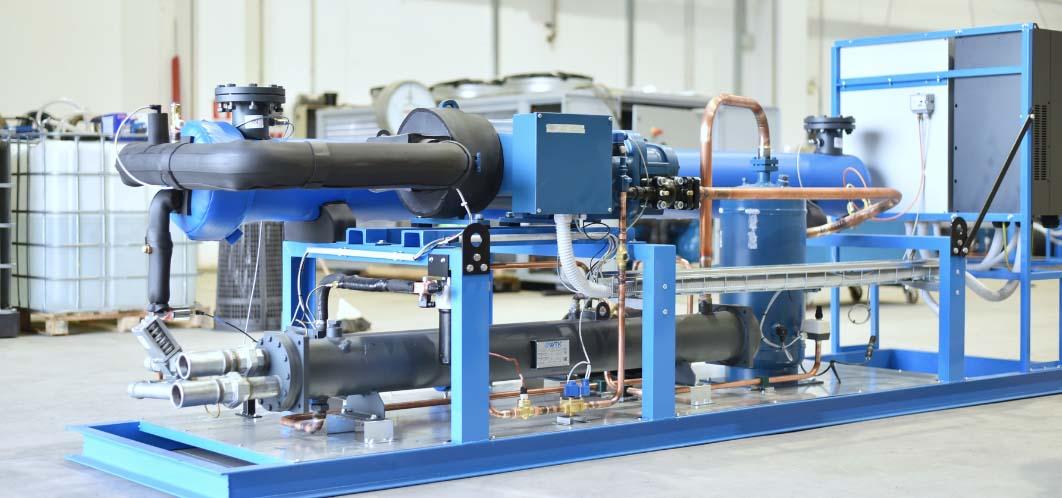

Two distinct installations united by a common element: the FVR-L screw compressors by Frascold, selected to overcome the application challenges connected to the needs of the respective customers. The result of the most recent teamplay between the technical teams of Frascold and A.S.K.I. – specialist in the design and manufacture of chillers for industrial refrigeration – are two chillers for low temperatures: the first intended for the food sector, and the second for the pharmaceutical sector, to provide the correct cooling load for use. Word to the experts: let’s learn more together with Giovanni Squassina, Owner and Technical Director of A.S.K.I., and Nika Bagdasarian, Frascold’s Sales Area Manager for North-West Italy.

Where does the creation of a chiller for the food sector come from?

“This first system came from the need of a company located in Mali, the eighth largest country in Africa, specialized in the production of fruit drinks. To best preserve their freshness and organoleptic qualities, we proposed a chiller that can cool a glycol water cold room, in favor of precise humidity control and very easy installation,” said Giovanni Squassina of A.S.K.I. “Storage is one of the key stages along the cold chain, during which it is necessary to ensure the total reduction of the product temperature and maintain the right conditions, for the very integrity of the food.”

In this application, what are the challenges you overcame thanks to Frascold’s FVR-L compressors?

“Thanks to the FVR-L compressors, the system is able to maintain a constant glycol temperature of -30°C, with an evaporation of -35°C, even in the hottest months, thus contributing to ensuring the safety and quality of the product. The component, guaranteeing a 5% higher COP than previous models, saves even more energy thanks to an inverter that precisely monitors the thermal load, thus reducing the number of machine starts and energy waste.” specified Nika Bagdasarian of Frascold.

The same compressors are also behind the second project. What are the peculiarities of this chiller?

“The FVR-Ls are ideal for many uses, also thanks to their wide range of cooling capacities,” commented Nika Bagdasarian, who continued, “In this second case, it is a chiller intended for the cooling load of the fluid (Glycol – Therminol – Temper) equal to -37°C. They constitute the essential part of a production system,” and concluded “The system is characterized by two compressors with step capacity control, on two separate circuits, each of which is equipped with an economizer which further improves its efficiency.”

Mr. Giovanni Squassina, why did you choose Frascold? What are its strengths?

“I have been relying on Frascold for the past 35 years, even before founding A.S.K.I. What unites us is a customer- and quality-oriented vision, with the desire to offer high-performance and reliable solutions, studied on a case-by-case basis. A care maintained by A.S.K.I. also through the testing of the chillers directly within the company: an additional advantage in terms of safety. Collaborating with Frascold means being supported by technicians with proven expertise and benefiting from punctual assistance and fast delivery.”