Frascold, together with Enrad, makes the most sustainable furniture factory in the world

Implementation of high-performance and sustainable heat pumps

Heat pumps with maximum energy saving and high performance, with Frascold compressors.

The collaboration between Frascold and ENRAD - a Swedish company specialised in designing and manufacturing natural coolant chillers and heat pumps in a standard module system - is getting stronger with a prestigious new project at The Plus, the most sustainable furniture production factory in the world, being built near Oslo. This outstanding site was created from the contractor’s desire to combine an eco-friendly approach with the latest technologies available on the market, becoming the first industrial building in the Nordic countries to receive Breeam Outstanding certification, the highest recognition for buildings in terms of efficiency and sustainability.

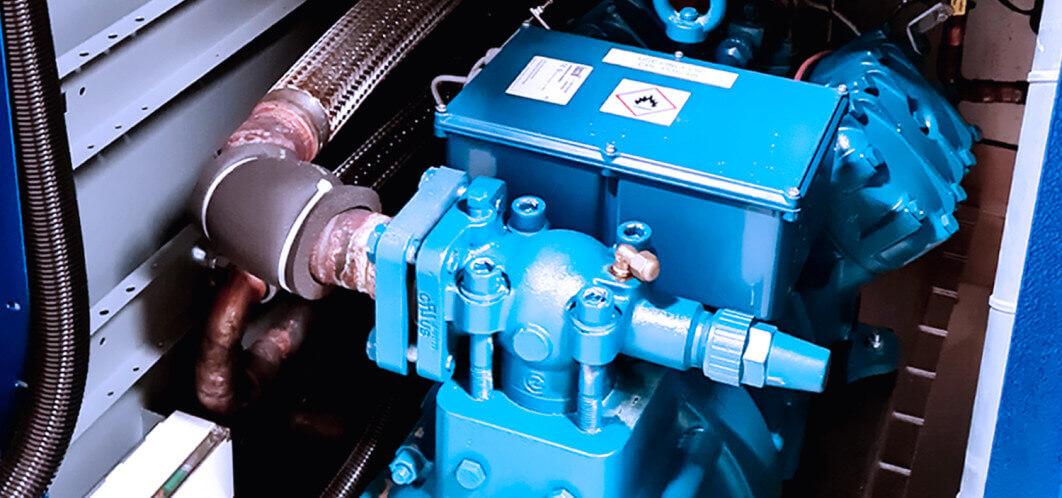

The design studio turned to ENRAD to meet this need: in fact, partly thanks to Frascold compressors, its heat pumps can guarantee maximum energy saving and high performance. This choice proved to be perfect both due to sharing the same system of values based on respect for the environment, quality, innovation and a proactive customer focus, and for the many benefits guaranteed by Frascold solutions in terms of reliability, maximum performance, efficiency - including under a partial load - and safety, ensured by compliance with the ATEX Directive. Thanks to an advanced control and regulation system, all the units are connected to guarantee constant optimisation of operations and swift resolution of any errors.

In particular, four heat pumps with reciprocating Z compressors for hydrocarbons have been installed inside the painting area, which perform cooling and heating functions for the process. Finally, confirming the unique nature of the system, another distinctive feature is the possibility of recovering any excess heat. This is used, together with the free-cooling geothermal plant for heating and cooling the manufacturing hub: a cutting-edge system that helps reduce the energy requirement of the production site by 90% compared with conventional factories.