CO₂ Heat Pump for the rail industry

Frascold and Aircodue revolutionize cooling and heating systems on trains

Introducing the ARCA project: a CO2 heat pump for the rail industry, the product of Aircodue’s unprecedented technological innovation and Frascold’s transcritical compressors.

Regulatory constraints and technological advancements in the rail industry

With a view to accelerating its energy transition, the rail industry is increasingly focusing on sustainability. Until now, innovation has been reflected in the enhanced efficiency of convoys powered by electric accumulators, and hydrogen-powered or battery-diesel hybrid trains. In this context, cooling and heating play a key role and represent a challenge for HVAC&R engineers at both a legislative and technological level. Specifically, the choice of refrigerant for use in cooling and heating systems is governed by regulations covering environmental aspects, such as the F-Gas standard, as well as fire safety and smoke control, which is subject to European standard EN 45545-2:2013. While the former aims to eliminate fluorinated greenhouse gases from the market, the latter defines the criteria for analyzing the behavior of the employed materials and components in case of fire and smoke and applies to different areas of the vehicles, including the fluids used and cooling systems.

Frascold and Aircodue together to promote sustainable progress

The close collaboration between Frascold and the start-up Aircodue – A Spin Off of the Miri Group, a leader in Renewable Energy and the Rail sector – has innovated the industry while adhering to the above-described regulations, thanks to the newly designed CO2 heat pump, distinguished by its multiple innovative technologies and supplied with Frascold transcritical compressors. The partnership was founded on four ambitious goals: reduced environmental impact, energy savings, lower maintenance costs, and high reliability, all in full compliance with national and international regulations.

ARCA: the project for natural cooling and heating

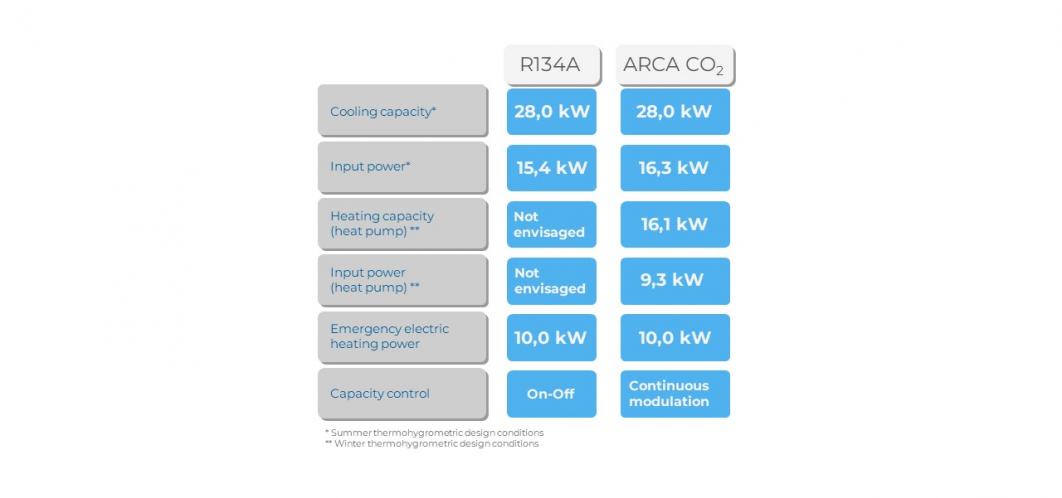

The Aircodue project called ARCA – Air Source Reversible CO2 Air Conditioner – employs patented technological solutions articulated in the demonstrator of a roughly 28 kW split system, rated to suit the demand of a railway carriage used for medium distances, which are very common in Italy. In cooperation with Frascold, the study analyzed whether it would be feasible to replace the existing system (drop-in) with a novel CO2 heat pump that could operate according to the previous configuration and meet the demands of the entire convoy. One precondition was that the new system must not require or absorb more power than the original R134A system, in which the static converter transforms the continuous current into an alternate current, supplying power to all the utilities on board. Specifically, the heat pump is made up of two parts: an external unit housing the compressors of the auxiliary and primary circuits, and an internal unit with a fan component used to heat and cool all the passenger areas.

In selecting the compressor most suited to the application, technical personnel used Frascold software to conduct a performance assessment across the entire operating range, subsequently opting for the D-TK model from the transcritical piston series. Synonymous with flexibility, high efficiency, and reliability, this type of compressor is designed to resist the high pressure of system standstills thanks to a sturdy design and standstill pressure of up to 100 bar (a), thus guaranteeing improved safety standards. The CapaFlexTM mechanical regulation is the series's defining feature, allowing modulation of the refrigerant flow rate transfer through suction inlets. The alternated closure and opening of the inlets ensures the correct partialization of the compressor, providing for more optimal loads and preventing on-off cycles as much as possible. A control mechanism for considerably higher performance. Another advantage of D-TK compressors is their low oil carryover, resulting in fewer leaks and ensuring the lubrication and protection of all moving parts.

Air Source Reversible CO2 Air Conditioner: a look at the figures

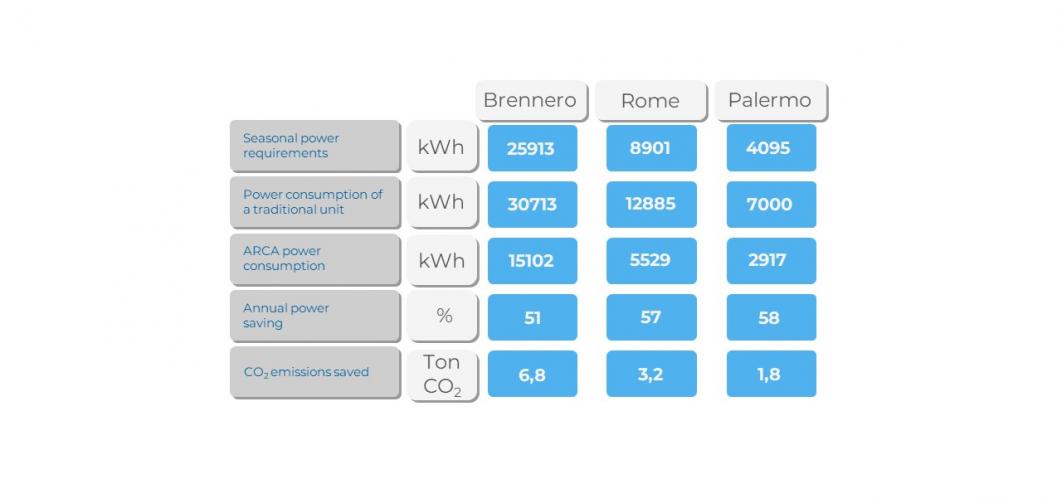

The heat pump’s performance data was compared with that of a traditional system, conducting a dynamic simulation of its operation in heating mode considering a wide range of winter temperatures. The study, carried out through the Energy Diagnosis of a medium-distance convoy and with the aid of appropriate software, considered three different reference locations indicative of Italy’s most important geographical areas, namely Brennero, Rome, and Palermo.

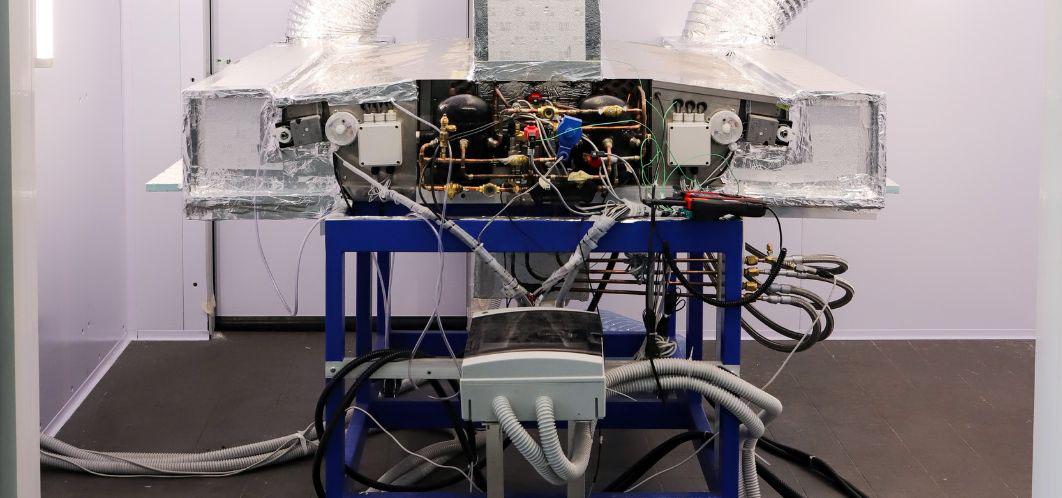

Once the prototype was completed, extensive testing was conducted in a climate chamber, allowing the cooling and heating performance to be determined and, therefore, the theoretical data to be confirmed.

Mirco Pasotti, Sales Area Manager at Frascold, states: “The study yielded numerous results. The heat pump effectively allows a 51–58% saving depending on the area, with a significant reduction in tonnes of CO2 emitted into the atmosphere.”

And Luigi Buttiglione, Technical Director at Aircodue, adds: “A project of considerable importance for the rail industry, where choosing a natural refrigerant requires an accurate assessment of both the installation and regulatory context.”

Giovanni Paone, Chairman of Aircodue, concludes: “CO2, in addition to being an efficient solution to fluorinated refrigerant phase-out policies, is also aligned with the environmental and safety policies of leading industry players. In this regard, Frascold’s specialized experience in the field has proven to be crucial. A long-standing partner with whom we continue to collaborate in the development of cutting-edge technology for the conscious evolution of the entire industry.”